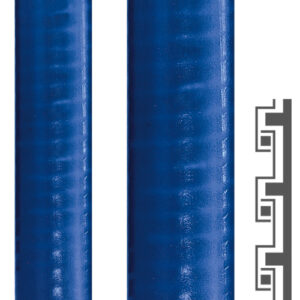

FLEXA – Others Conduits (Fleks Conduit)

Our other specialized products include liquid-tight metal protection conduits with smooth surfaces and fire protection conduits.

Engineered for High Performance and Reliability in Flexible Cable and Pipe Routing

Flexa’s “Fleks Konduit” solutions are specially developed for professionals seeking high performance and reliability in flexible cable and conduit routing systems. This product group offers excellent routing capability in demanding environments due to its flexible structure, while also providing effective protection against external factors to ensure system continuity.

Flexible and Functional Design

Flexible conduit systems are particularly advantageous in confined spaces where routing cables or pipes is challenging. They offer ideal solutions for the mechanical protection and safe guidance of cables and hoses. Thanks to their spiral construction, they exhibit outstanding adaptability to bending, vibration, and dynamic motion from moving equipment.

Application Areas

These systems are reliably used across a wide range of sectors, including automation systems, machinery manufacturing, railway applications, power distribution infrastructure, building electrification, and renewable energy systems. Flexa’s flexible conduit systems are preferred in both stationary and dynamic applications and perform exceptionally well in cable carrier systems that require constant motion.

Technical Specifications

The product range includes hoses made of PVC, polyamide (PA6/PA12), TPE, polypropylene, and metal-coated variants to meet various requirements. Options are available with flame-retardant, halogen-free, UV-resistant, chemical-resistant, and oil-resistant properties. They are manufactured in different diameters and colors, facilitating system identification and cable management.

Installation and Compatibility

When used in combination with Flexa’s extensive accessory portfolio, flexible conduit systems allow for fast, secure, and user-friendly installation. With support from threaded connectors, snap-in adapters, and clamps, they can be easily integrated into various system architectures.

Advantages

-

High flexibility and ease of use in tight spaces

-

Resistance to mechanical impacts and vibrations

-

Protection against UV exposure, moisture, and chemicals

-

Application versatility with various material options

-

Compliance with international standards such as EN and UL

| Brand |

Flexa |

|---|