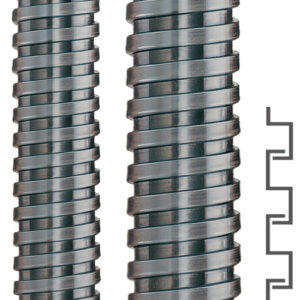

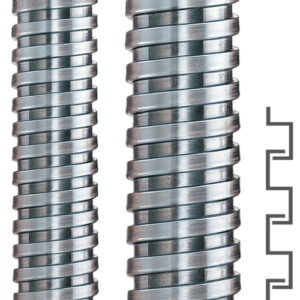

FLEXA – Unjacketed Metal Conduits (Fleks Conduit)

Our conduits offer a high level of mechanical impact and abrasion resistance. Industrial applications, especially those used in production environments, place significant demands on cables and associated cable protection systems.

Reliable, Long-Life Solutions for Maximum Mechanical Protection

Flexa’s uncoated steel spiral conduit systems provide dependable and long-lasting solutions for applications that demand maximum mechanical protection. Without an outer sheath, these conduits rely entirely on their steel construction to offer high resistance to impact, crushing, and elevated temperatures. These systems are a fundamental component of professional cable management, particularly in environments with intense physical stress.

Construction and Technical Features

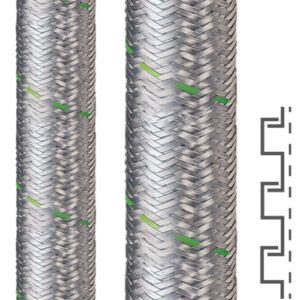

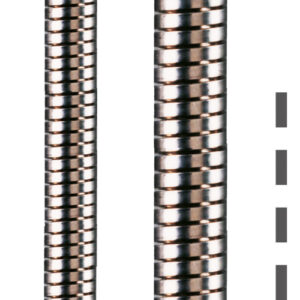

Uncoated conduit systems consist of spiral tubes made entirely of galvanized or stainless steel. This structure combines exceptional bendability with the ability to safeguard cables in harsh environments. As there is no external sheath, these conduits are especially suitable for applications that do not require chemical resistance or sealing properties.

Application Areas

Flexa’s uncoated spiral conduits are commonly used in machinery manufacturing, heavy industry, control panels, industrial robotics, and indoor installations. They are especially preferred in indoor environments where protective sheathing is unnecessary but high mechanical strength is critical. These systems are also frequently used in critical sectors such as railway and defense industries.

Advantages

-

High mechanical protection and bending resistance

-

Resistance to heat and physical impact

-

Compact and lightweight due to absence of sheath

-

Cost-effective and minimalistic design

-

Corrosion resistance with stainless steel variants

Installation and Integration

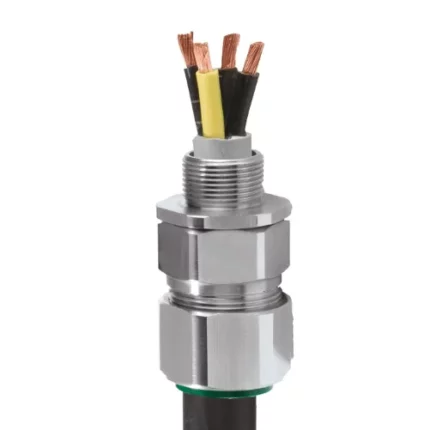

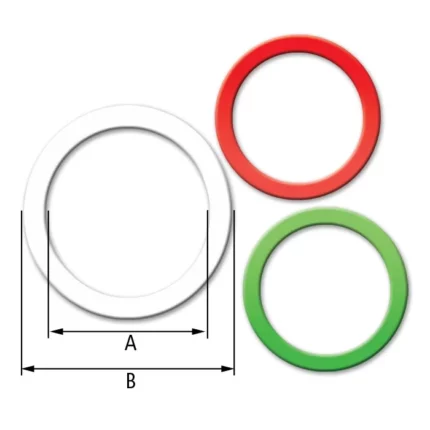

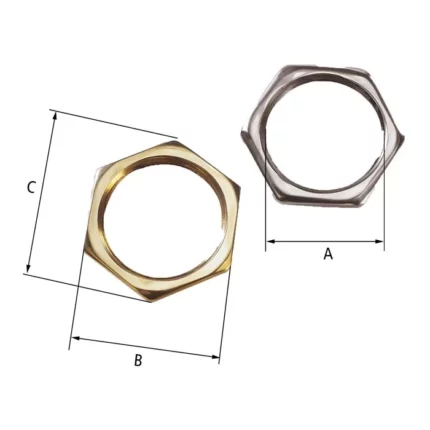

When used with Flexa’s specialized connectors, these conduits form tight and robust connection points. Compatible with threaded or snap-in connectors, the system integrates easily with panels, machine surfaces, and cable duct systems. The spiral structure allows flexibility in directional changes, reducing installation time.

Application Flexibility

Uncoated steel spiral systems are ideal for indoor use, while stainless steel versions are recommended for outdoor applications. These systems also support ease of maintenance and retrofitting—they can be cut and reassembled as needed.

| Brand |

Flexa |

|---|