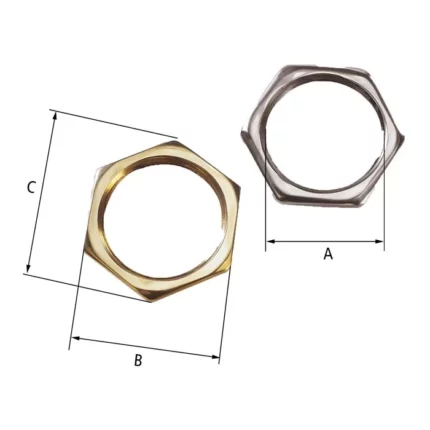

FLEXA – Metal Connectors

Our connection technology consists of metal fittings in straight, swivel, bent, angled, or strain relief versions, along with sealing rings, inner sleeves, and terminal sleeves.

Designed for Secure, Sealed, and Robust Connections in Harsh Industrial Environments

Flexa metal connectors are engineered to ensure safe, sealed, and durable connections in cable and conduit protection systems operating under demanding industrial conditions. With features such as high mechanical strength, long service life, and strong resistance to environmental influences, these connectors play a critical role in heavy-duty and outdoor applications.

Durable Material Composition

Flexa’s metal connectors are typically manufactured from high-grade materials such as brass, nickel-plated brass, or stainless steel (AISI 303/304/316). This construction provides maximum resistance to impacts, vibrations, high temperatures, and chemical exposure. Their robust metal structure makes them a reliable choice for applications requiring both mechanical and environmental durability.

Common Application Areas

-

Automotive and railway industries

-

Mechanical engineering

-

Industrial automation and robotics

-

Renewable energy facilities

-

Chemical and petrochemical industries

-

Shipbuilding and outdoor electrical installations

Metal connectors are especially used for sealed integration of conduit systems with electrical panels, machinery surfaces, or field devices. Their wide range of diameters enables compatibility with various hose and conduit types.

Technical Specifications

-

IP66 / IP68 / IP69K ingress protection ratings

-

Threaded or snap-in connection options

-

Available in straight, 45°, and 90° angled versions

-

Internal thread / external thread / push-fit types

-

Halogen-free and RoHS-compliant construction

-

Flame-retardant and corrosion-resistant features

Ease of Installation and Compatibility

Flexa metal connectors are highly compatible with both spiral metal hoses and flexible plastic conduit systems. Installation is straightforward—allowing quick connection and disassembly, which facilitates maintenance and system modifications. Even in high-vibration environments, these connectors maintain reliable and sealed connections.

Advantages

-

High sealing performance and secure connectivity

-

Resistance to extreme environmental conditions

-

Compliance with industrial standards

-

Flexible solutions with a broad product portfolio

| Brand |

Flexa |

|---|