FLEXA – Jacketed Metal Conduits (Fleks Conduit)

Our liquid-tight metal conduits are flexible and can be coated with various materials. Depending on the material combination, they offer resistance to oil, acids, microbes, and moisture.

Professional Solutions for High Mechanical Protection and Environmental Resistance

Flexa’s sheathed steel spiral conduit systems offer professional-grade solutions for applications requiring both high mechanical protection and strong environmental resistance. While maintaining flexibility, these conduit systems ensure superior protection against external factors and play a critical role in industrial cable management.

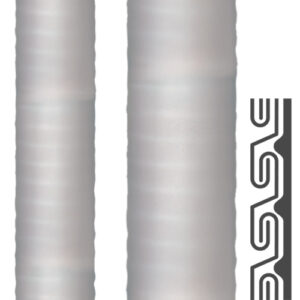

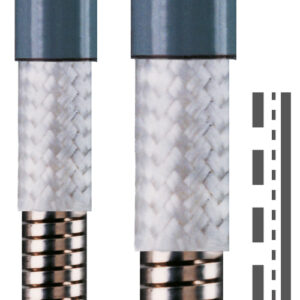

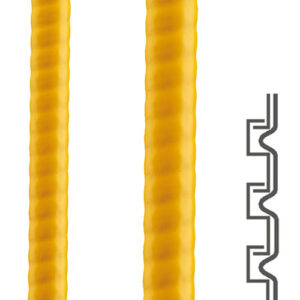

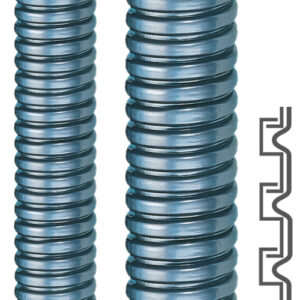

Construction and Material Properties

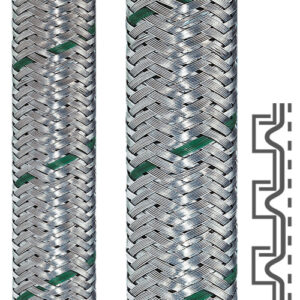

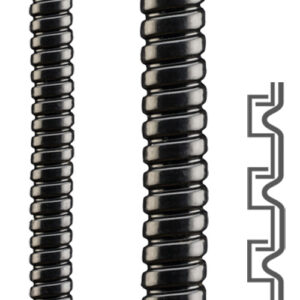

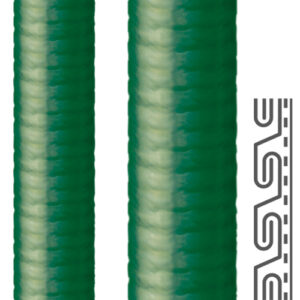

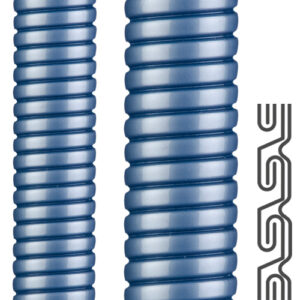

These systems consist of an inner galvanized or stainless steel spiral conduit, combined with an outer sheath made of plastic (e.g., PVC, PU, TPE) or fabric-based materials. The inner steel spiral provides high resistance against mechanical impacts, bending, and crushing, while the outer sheath protects against environmental influences. Depending on the sheath material, long-lasting durability is achieved even under exposure to UV rays, chemicals, oils, water, and extreme temperature variations.

Application Areas

Flexa’s sheathed steel spiral systems are widely used in mechanical engineering, automotive production lines, railway systems, robotic applications, power plants, and outdoor installations. They are an ideal solution for protecting and routing cables or hoses in both static and dynamic applications.

Technical Advantages

-

High mechanical strength

-

Resistance to abrasion and impacts

-

Flexible structure allowing excellent bendability

-

Halogen-free, flame-retardant, and UV-resistant sheath options

-

Various temperature ranges available (e.g., -40°C to +125°C operating range)

Easy Installation and System Compatibility

When combined with Flexa’s specially designed connectors and clamps, the sheathed steel conduits provide a sealed, robust, and user-friendly installation process. Threaded or snap-in connector options allow quick integration with different surfaces. Moreover, the system’s ability to be disassembled and reinstalled ensures convenient maintenance.

Use Case Scenarios

In outdoor wiring, heavy industrial facilities, or high-vibration environments, these conduit systems extend cable life and enhance system safety. Thanks to the corrosion-resistant steel core and protective sheath combination, the system operates reliably even under the harshest conditions.

| Brand |

Flexa |

|---|