Blog

Explosion-Proof Equipments: Usage and Requirements

Explosion-proof equipment is the optimal choice for workers in hazardous areas, but do you know how this equipment operates? Let’s explore this topic in this article.

When researching explosion protection, you often come across the term “Ex-proof.” It’s a common question to determine the best safety strategy for hazardous areas. For instance, climbers have different plans for their ascents: they have different routes to the same summit, but one may be better depending on the conditions. It would be wise to assess before deciding which path to take.

Definition of 'Explosion Proof' (Ex-proof)

The “Ex” mark defines explosion-proof equipment and is an adopted safety strategy for hazardous areas. It remains one of the pioneering safety strategies, yet its operation continues to intrigue.

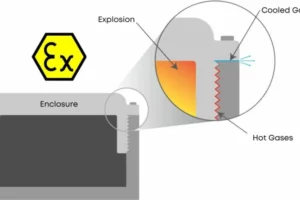

What defines equipment as Ex-proof is its enclosure that is capable of preventing damage in hazardous locations prone to explosions. An explosion can create pressure inside the equipment enclosure. This pressure can dissipate sparks and prevent a worse accident. To ensure equipment is Ex-proof, it must be certified according to appropriate safety regulations such as NEC, NFPA, UL, and others.

How does explosion-proof equipment work?

This type of equipment is designed to withstand explosions originating from gases or vapors. In other words, if a spark occurs inside the equipment, its casing will be strong enough to prevent the explosion from dispersing into the external atmosphere. Let’s understand how this design ensures safety at this level.

When an internal explosion occurs within the equipment, the gas expelled under pressure seeks a way out of the enclosure. Understanding this, the design of Ex-proof equipment ensures that the gas cools down without escaping to the outside.

The reinforced enclosure helps internally dissipate the gas by cooling it and preventing pressure from escaping. This method is endorsed by global safety standards. However, if the quality of materials used for the casing is not adequate, this measure may not suffice. Minor external damages can jeopardize the product certification and lead to accidents. Refer below for examples of how the enclosure operates.